Due to the strict environmental norms, coal-based power plants across India are in the process of installing & upgrading FGD systems, ESPs and other air pollution control equipments. An opportunity of approximately 166 GW lies under for APCE value chain players till 2022.

India’s new emission norms by 2022

To meet India’s new emission norms by 2022, a large number of coal-based thermal power plants have to install FGD systems. Limestone is a key raw material in most FGD systems for controlling sulphur dioxide (SO2) emissions. Flue gas desulphurization – limestone availability and gypsum use, as the CSE report is titled, attempts to examine the issue of availability of limestone for FGD.

Key Topics Covered:

- Contents and Coverage FGD & APCE Market in India – Know How & Impact of Pandemic Market Opportunity for FGD & APCE for Industrial Usage till 2025

- Market Opportunity for FGD & APCE for end-use type till 2025

- Demand Assessment & Opportunity Examination for FGD Systems & APCE by Equipment Wise Type till 2025

- Examining the Market Share, Market Size and Competition Landscaping of Major OEMs in FGD & APCE Market

- Maintenance, Repair & Overhaul (MRO) Market Opportunity for FGD Systems & APCE in India till 2025

- Region-Wise Market Opportunity for FGD Systems and APCE in India Till 2025

- Market Opportunity Split for Key-Value Chain Players in FGD & APCE Market in India till 2025

India’s window for using coal reserves may last 20-30 years: Pralhad Joshi

Flue Gas Desulphurisation: A Rs 80,000 crore investment opportunity

Flue gas desulfurization (FGD)

A flue gas desulfurization (FGD) processing unit, commonly referred to as a scrubber, removes sulfur dioxide (SO2) from the exhaust flue gases in power plants that burn coal; airborne SO2 forms acid rain. As environmental emissions regulations for sulfur dioxide tighten in countries worldwide, technologies for SO2 removal and associated analysis continue to advance.

List of manufacturing companies for Flue gas desulfurization (FGD) Systems

- BHEL

- L&T

- GE

- Thermax India

- BGR Energy and

- Shapoorji Pallonji

What is the process of flue gas desulphurisation?

The Flue-Gas Desulfurization (FGD) process utilizes a set of technologies to remove sulfur dioxide (SO2) from the flue gas emissions of coal-fired power plants. … S02 can be removed from flue gases by a variety of methods. For a typical coal-fired power plant, FGD systems will remove ~95% of the SO2 in the flue gases.

Is Limestone used to desulfurize flue gases?

Lime plays a key role in many air pollution control applications. Lime is used to remove acidic gases, particularly sulfur dioxide (SO2) and hydrogen chloride (HCl), from flue gases.

What is Limestone?

Limestone is a type of carbonate sedimentary rock. It is composed mostly of the minerals calcite and aragonite, which are different crystal forms of calcium carbonate. A closely related rock is dolomite, which contains a high percentage of the mineral dolomite, CaMg(CO₃)₂.

- Limestone rocks are composed of either calcium carbonate, the double carbonate of calcium and magnesium, or mixture of both.

- Limestone also contains small quantities of silica, alumina, iron oxides, phosphorus and sulphur.

- Limestone deposits are of sedimentary origin and exist in all the geological sequences from Pre-Cambrian to Recent except in Gondwana.

- 75 per cent Limestone is used in cement industry, 16 per cent in iron and steel industry [It acts as flux] and 4 per cent in the chemical industries.

- Rest of the limestone is used in paper, sugar, fertilizers, etc.

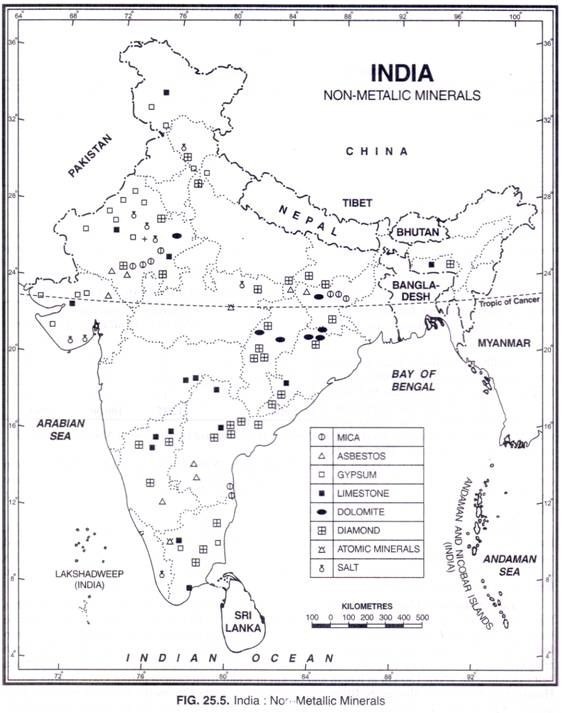

- Almost all the states of India produce some quantity of limestone.

- Over three-fourths of the total limestone of India is produced by Madhya Pradesh, Rajasthan, Andhra Pradesh, Gujarat, Chhattisgarh and Tamil Nadu.

Limestone deposits in India

Say CSE researchers behind the report: “The coal-based power sector would require only seven to 10 million tonnes of limestone annually for operating FGD systems. This is less than 3 per cent of India’s present limestone consumption.

Andhra Pradesh and Telangana put together possess 32% of the country’s total reserves of limestone. world renowned Narzi limestone is available in kadapa district. Commercial grade limestone deposits are being exploiting from Bethamcherla, Macherla, Neereducherla, Tandur, ((shahabad)), Mudimanikyam of Kurnool, Guntur, Anantapur, Rangareddy, and Nalgonda districts are widely used in our country for panelling, and flooring purposes. Sullavai limestone of Karminagar and Warangal districts, massive limestones of Mudimanikyam, Nalgonda districts. Total India’s limestones are estimated about 93,623 million tonnes. Limestones are extensively utilised for manufacturing of cement and also building stones, particularly flooring and roofing.

Limestone mining company in india

- National Mineral Development Corporation.

- Vedanta.

- Hindustan Zinc.

- Hindustan Copper.

- Hindalco Industries.

- Bharat Aluminium Company.

- Rajasthan State Mines and Minerals.

- Gujarat Mineral Development Corporation.

Gypsum vs Limestone

Gypsum & Limestone: two great soil amendments with key differences. Gypsum is calcium sulfate, and lime is calcium carbonate. Both are soil amendments, and both provide calcium. … And the higher the sulfur content of the coal, the greater the amount of synthetic gypsum produced.

Reference

- https://www.ncbi.nlm.nih.gov/books/NBK525204/

- https://www.cseindia.org/thermal-power-plants-meet-the-new-emission-norms-says-cse-s-new-report-10044

- https://www.financialexpress.com/opinion/flue-gas-desulphurisation-a-rs-80000-crore-investment-opportunity/1987779/